GE 200NG-MAN2876-EN

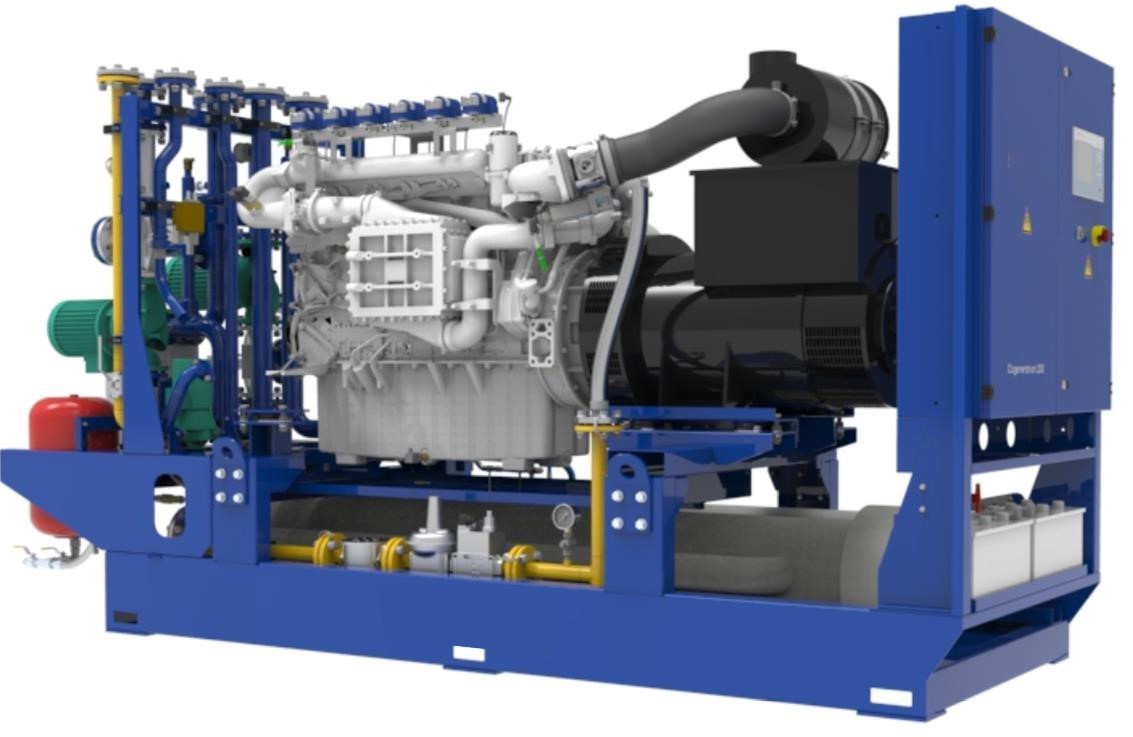

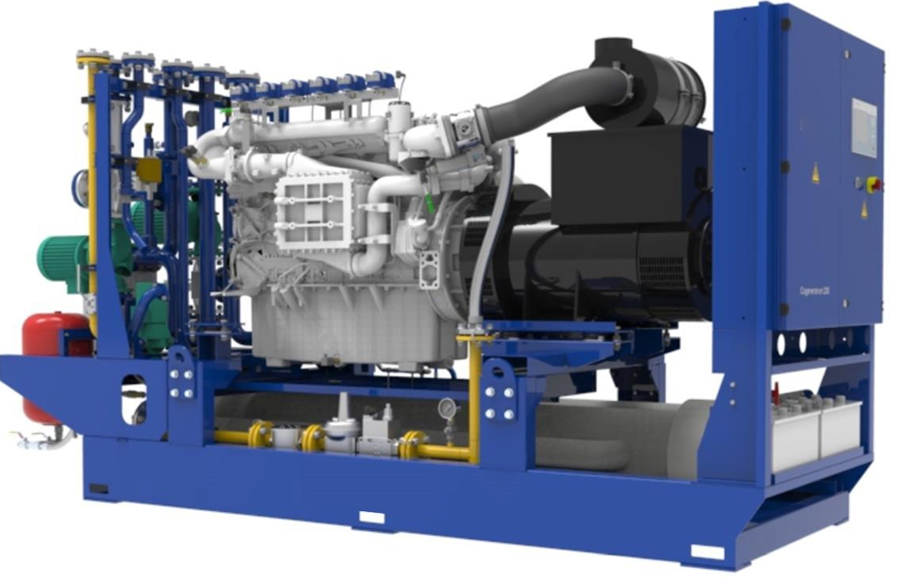

200NG/200NGS

Natural gas Generator Set

Main configuration and features:

• Highly efficient gas engine. & AC synchronous alternator.

• Gas safety train and gas protection device against leakage.

• Cooling system suitable for ambient temperature up to 50℃.

• Strict shop test for all gensets.

• Industrial silencer with silencing ability of 12-20dB (A).

• Advanced engine control system: ECI control system including: ignition system, detonation control system ,speed control system , protection system,air/fuel ratio control system and cylinder temp.

• With cooler and Temperature Control System to make sure the unit can work normally at 50℃ environment temperature.

• Independent electrical control cabinet for remote control.

• Multi-functional control system with simple operation.

• Data communication interfaces integrated into control system.

• Monitoring battery voltage and charging automatically.

| Unit type data | |||||||||||||||

| Fuel type |

Natural gas |

||||||||||||||

| Equipment type |

200NG/200NGS |

||||||||||||||

| Assembly |

Power supply + exhaust gas heat exchanger kit + Control cabinet |

||||||||||||||

| Genset compliance with standard |

ISO3046,ISO8528,GB2820, CE,CSA,UL,CUL |

||||||||||||||

| Continuous output | |||||||||||||||

| power modulation |

50% |

75% |

100% |

||||||||||||

| Electrical output | kW |

100 284 |

150 423 |

200 537 |

|||||||||||

| Fuel use | kW | ||||||||||||||

| Efficiency in mains parallel mode | |||||||||||||||

| Continuous output |

50% |

75% |

100% |

||||||||||||

| Electrical efficiency % |

34.3 |

35 |

37.1 |

||||||||||||

| Current(A)/ 400V / F=0.8 |

|

|

|

||||||||||||

Special statement:

1. The technical data are based on natural gas with a calorific value of 10 kWh/Nm³ and a methane no. > 90%

2. The technical data are based on biogas with a calorific value of 6 kWh/Nm³ and a methane no. > 60%

3. The technical data indicated is based on standard conditions according to ISO8528/1, ISO3046/1 and BS5514/1

4. The technical data is measured in standard conditions: Absolute atmospheric pressure:100kPa Ambient temperature:25°C Relative air humidity:30%

5. Rating adaptation at ambient conditions according to DIN ISO 3046/1.The tolerance for the specific fuel consumption is + 5 % at rated output.

6. Documentation technical parameters are for standard product use only and are subject to change. As this document is for pre-sale reference only, the final order is subject to the technical specifications provided.

| Prime power Operating Data Insolated Mode | |||||||||||

| Synchronous alternator |

Star, 3P4h |

||||||||||

| Frequency | Hz |

50 |

|||||||||

| Power factor |

0.8 |

||||||||||

| Rating (F) KVA prime power | KVA |

250 |

|||||||||

| Generator voltage | V |

380 |

400 |

415 |

440 |

||||||

| Current | A |

380 |

361 |

348 |

328 |

||||||

| Genset performance data and manufacturing technology | |||||||||||

| Overload run-time at 1.1xSe(hour) |

1 |

Telephone interference factor (TIF) |

≤50 | ||||||||

| Voltage setting range |

≥±5% |

Telephone harmonious factor (THF) |

≤2%,as perBS4999 | ||||||||

| Steady-state voltage deviation |

≤±1% |

Manufacturing technology

Standards and certificate

|

|||||||||

| Transient-state voltage deviation |

-15%~20% |

||||||||||

| Voltage recovery time (s) |

≤4 |

||||||||||

| Voltage unbalance |

1% |

||||||||||

| Steady-state frequency regulation |

±0.5% |

||||||||||

|

Transient -state frequency regulation |

-15%~12% |

||||||||||

| Frequency recovery time (s) |

≤3 |

||||||||||

| Steady-state frequency band |

0.5% |

||||||||||

| Recovery time response (s) |

0.5 |

||||||||||

| Line Voltage Waveform Sine Distortion Ratio |

≤ 5% |

||||||||||

| Emission data[1] | |||||||||||

| Exhaust flow rate | 1120 kg/h | ||||||||||

| Exhaust temperature | 60℃~120℃ | ||||||||||

| Maximum allowable exhaust back pressure | 2.5Kpa | ||||||||||

| Emission: (Option) NOx: | < 500 mg/Nm³ at 5% residual oxygen | ||||||||||

| CO | ≤600 mg/ Nm³ at 5% residual oxygen | ||||||||||

| NMHC | ≤125 mg/ Nm³ at 5% residual oxygen | ||||||||||

| H2S | ≤20 mg/ Nm3 | ||||||||||

| Environmental noise | |||||||||||

| Sound pressure level at a distance of up to 1 m(based on surroundings) |

87dB (A) / Open Type 75dB (A) / Silent Type |

||||||||||

[1] Emission values downstream of catalytic converter based on dry exhaust.

|

[2] maintenance time shall be subject to the application environment, fuel quality as well as maintenance intervals; the data is not offered as the basis for sales.

Alternator compliance withGB755, BS5000, VDE0530, NEMAMG1-22, IED34-1, CSA22.2 and AS1359 standard. In case of nominal mains voltage variations by ± 2%, an automatic voltage regulator (AVR) must be used. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Scope of Supply | ||||||

| Engine | Alternator Canopy and base Electrical cabinet | |||||

| Gas engine Ignition system Lambda controllerElectronic governor actuatorElectrical start motorBattery system | AC alternatorH class insulationIP55 protectionAVR voltage regulatorPF control | Steel sheel base frameEngine bracket Vibration isolators Soundproof canopyDust filtration | Air circuit breaker7-inch touch screenCommunication interfaces Electrical switch cabinetAuto charging system | |||

| Gas supply system | Lubrication system | Standard voltage | Induction/exhaust system | |||

| Gas safety trainGas leakage protectionAir/fuel mixer | Oil filterDaily auxiliary oil tankAuto refilling oil system | 380/220V400/230V415/240V | Air filterExhaust silencerExhaust bellows | |||

| Gas Train | Service and documents | |||||

| Manual cut-off valve2~7kPa pressure gaugeGas filterSafety Solenoid valve (anti-explosion type is optional) pressure regulatorFlame arrestor as option | Tools package Engine operation Installation and operation manual Gas quality specification Maintenance manual Control system manual Software manual After service guide Parts manual Standard package | |||||

| Optional configuration | ||||||

| Engine | Alternator | Lubrication system | ||||

| Coarse air filterBackfire safety control valveWater heater | Synchron – generator Brand: Stamford, LeroySomer, MECCTreatments against humidity and corrosion | Brand new oil tank with large capacityOil consumption measuring gaugeFuel pumpOil heater | ||||

| Electrical system | Gas supply system | Voltage | ||||

| Remote monitoring Grid-connection remote control sensor | Gas flow gaugeGas filtrationPressure reducer gas pretreatment alarm system | 220V230V240V | ||||

| Service and documents | Exhaust system | Heat exchange system | ||||

| Service toolsMaintenance and service parts | Three-way catalytic converterGuard shield from touchResidential silencerExhaust gas treatment | Emergency radiatorElectric heaterThermal storage tankPumpFlowmeter | ||||

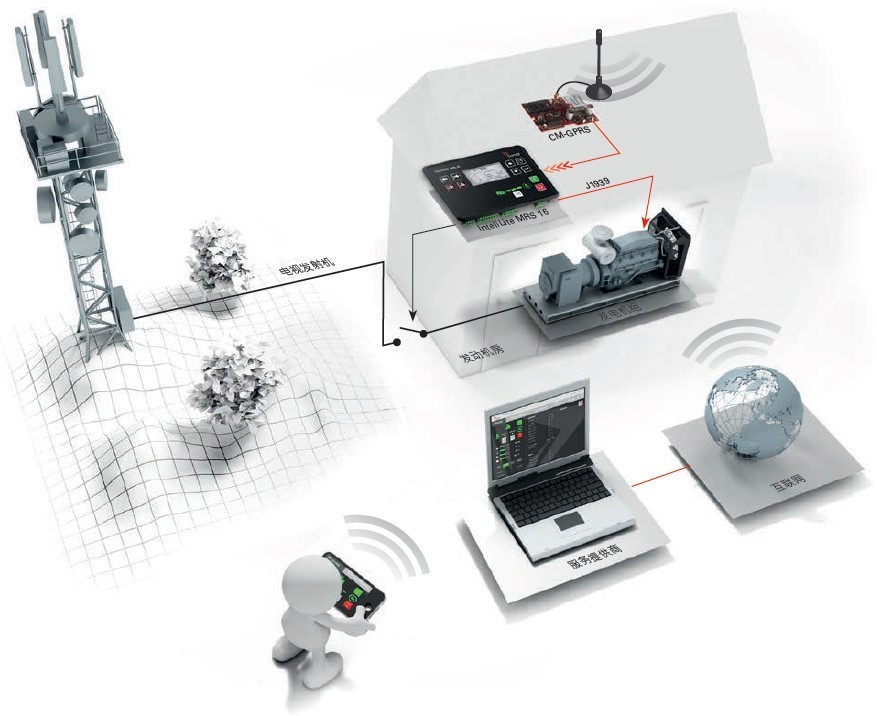

SAC-300 Control system

Programmable control system is adopted with touch screen display , and various functions, including: engine protection and control. paralleling between gensets or gensets and grid, and CHP control functions, as well as communication functions. etc.

Main advantages

→ Premium gen-set controller for both single and multiple gensets operating in standby or parallel modes.

→ Support of complex applications for power production in data centres, hospitals, banks and also CHP applications.

→ Support of engines both with electronic unit – ECU and mechanical engines.

→ Complete control of the engine, alternator and controlled technology from one unit provides access to all measured data in a coherent and time corresponding way.

→ Wide range of communication interfaces allows smooth integration into local monitoring systems (BMS, etc.)

→ Internal built-in PLC interpreter allows you to configure customised logic to meet demanding customer requirements on your own without extra programming knowledge and in a fast way.

→ Convenient remote control and service

→ Enhanced stability and safety

| Main functions | |||||

| Engine monitor:coolant, lubrication, exhaust, battery Fuel gas inlet loop monitoring Parallel connection and power distribution automaticallyVoltage and power factor controlUnit monitoring and protectionModbus communication protocol based on RS232 and RS485 interfaces 1000 history events log Remote control

Parallel and grid connection system |

Protection with IP44Set Input, Output, Alarm and Time Automatic failure state emergency stop and fault display LCD display functionExtensible FunctionATS (Automatic Transfer Switch)GPRS function with SMSUtomatic floating charger Gas leaking detection | ||||

| Standard configuration | |||||

| Engine Control: Lambda closed loop controlIgnition systemElectronic governor actuatorStart up control speed control load control | Generator Control:Power control RPM control (synchronous) Load distribution (island mode) Voltage control | Voltage tracking (synchronous) Voltage control (island mode)Reactive power distribution(island mode) | Other controls: Oil filling automaticallyWater pump controlValve control Fan control | ||

| Early warning monitoring | |||||

| battery voltageAlternator data:U、I、Hz、kW、 kVA、kVAr、PF、kWh、kVAhGenset frequency | Engine SpeedEngine running timeInlet pressure temperatureOil pressureOil Temperature | Coolant temperatureMeasurement of oxygen content in exhaust gasIgnition status inspection | Coolant temperatureFuel gas inlet pressurePressure and temperature of the heat exchanger system | ||

| Protection functions | |||||

| Engine protection Low oil pressureSpeed protectionOver speed/short speedStarting failureSpeed signal lost | Alternator protection- 2xReverse power- 2xOverload- 4xOvercurrent- 1xOvervoltage- 1xUndervoltage- 1xOver/under frequency- 1xUnbalanced current | Busbar/mains protection - 1xOvervoltage- 1xUndervoltage- 1xOver/under frequency- 1xPhase sequence - 1xROCOF alarm | System protection Alarm Protection FunctionHigh coolant temperatureCharge faultEmergency Stop | ||

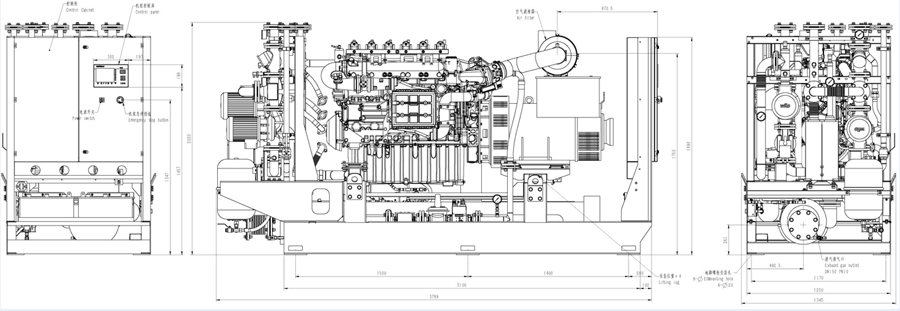

Dimensions are for reference only.

| Paints, Dimensions and Weights of the Genset | |

| Genset size (length * width * height) mm | 3880×1345×2020 |

| Genset dry weight(Open Type) kg | 3350 |

| Spraying Process | High quality powder coating(RAL 9016 & RAL 5017 ) |